Remoulding the helmet

Re-moulding the Iron Man Helmet

This page is about remoulding the helmet, check out the main project index for the rest.

Once I had cleaned up the original helmet I made a new mould from it. This is so I could make new casts of the helmet to make new variations without going through the whole clean up process every time. The original mould was quite simple, but this version is split into two halves to allow fibreglassing, and easier cast removal.

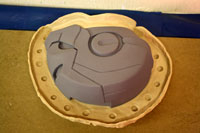

Firstly I divided the helmet into two using a piece of wood and some clay. I’ve made a channel around the edge with holes in which will eventually be my keyed edge of one half of the mould.

I then covered that side of the helmet with Silicone RTV which is unthickened, followed by two thickened coats, some lumps of silicone made in ice cube moulds, and one last coat of unthickened silicone to make the surface smooth. The lumps will serve as registration keys in the rigid mother mould which comes next:

Here’s the rigid mothermould which is made from Jesmonite liquid and some Yellow dental stone I had lying about, it’s reinforced with glass fibre mat:

Next I turned the whole thing up the other way, and removed the clay wall:

Very Important – the exposed edge of the silicone was sealed with Vaseline (or a similar petroleum jelly). This is to stop the two halves sticking together. Then the moulding process was repeated on this side:

And the rigid mother mould was again added. After that the mould could be split in two, the original removed, and we’re ready to make some more casts. You notice that the two halves now have corresponding lumps and holes that mean they fit together in the right place: